The low-pressure filter is used in all those machines operating with air in their system, therefore needing cleaning systems to filter the air before reinserting it in the ambience. For this reason, it is mainly used for pneumatic conveying systems or aspiration systems.

G&AS filters employ cyclonic settling through the tangential inlet in the first place; then the air passes through a group of filtering sleeves, going from the outside to the inside, thus dropping the dust off on their external surface.

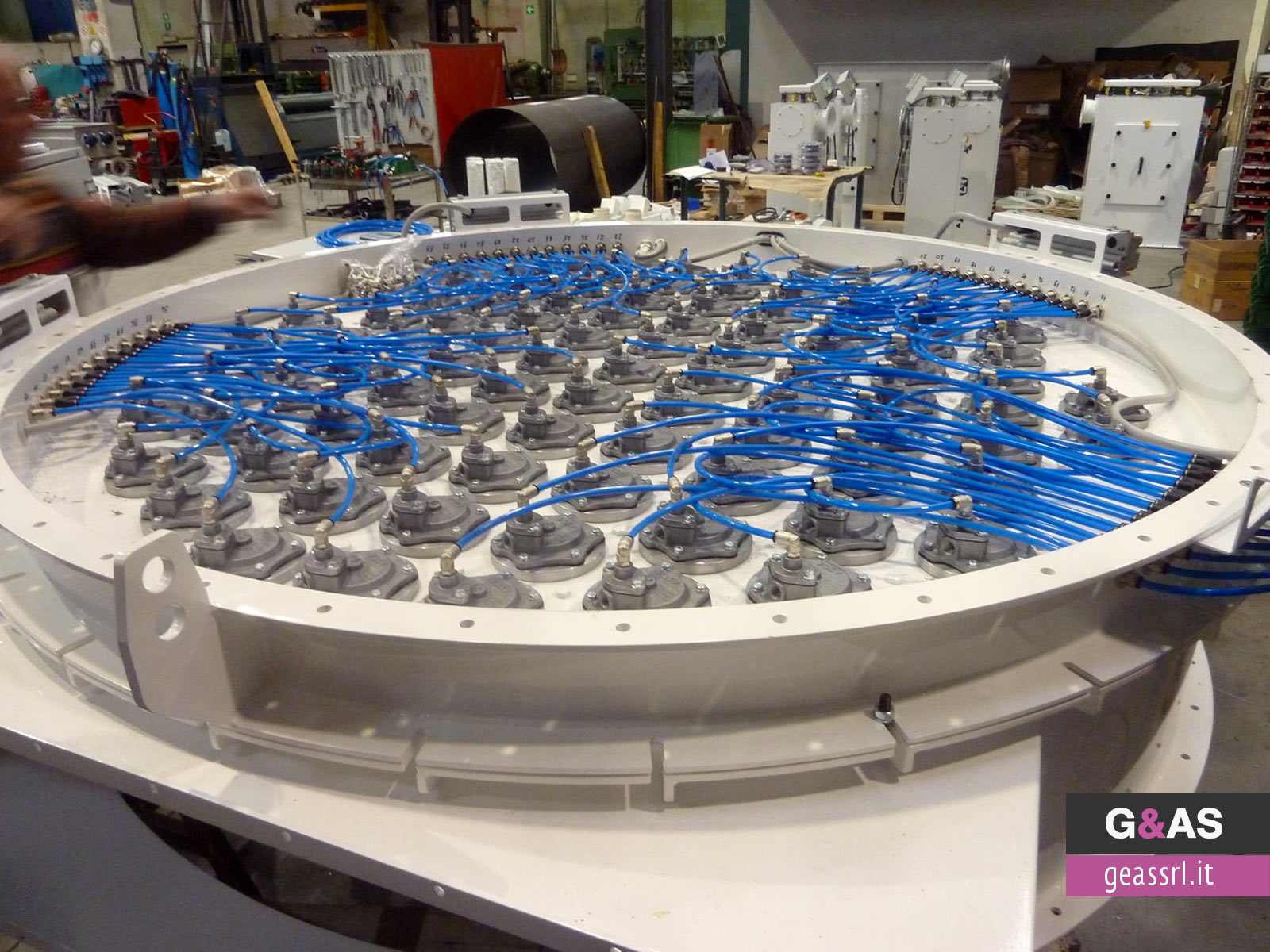

A temporised upstream jet of air cleans cyclically the filtering fabric.

The low-pressure jet filter uses compressed air at 0,5 – 0,6 bars. The air enters the head filter, which serves also as reservoir, then goes inside each filtering sleeve through pneumatic valves. The steering electrovalves are placed outside the filter and are controlled by an electronic programmable sequencer.

The low-pressure filter is composed of cylindric elements made of metal sheet, joined together through bolts. It can be flat bottomed, equipped with a motorised extracting impeller or with a discharge cone. The powder is discharged through a star valve that prevents the air from entering the system.

The air goes inside the filter to be processed: the heavy particles of dust go down towards the outlets while the light ones, carried in suspension, are deposited on the external surface of the sleeves, letting only the depurated air pass through. An electrical adjustable temporiser controls the emission of compressed air inside the sleeves, thus causing them to expand, while dust detaches and fall to the bottom of the filter and is therefore discharged through the rotating valve. Upon request the filter can be equipped with certified anti-explosion panels or with flame arrester.

Several electronic systems are available to control, also remotely, the filter operation.

Operation pressure of the filter ranges from + 0.8 bars to – 0.5 bars.

Operation pressure of the sleeves cleaning system is 0,5 – 0,6 bars

A pressure gauge constantly checks on every possible pressure drop of the sleeves, showing if they need to be changed or cleaned. Their examination, maintenance and replacement can be performed easily through a large hatch and through other vents. Sleeves can be easily and quickly replaced through a bayonet system.